Creactivity can be an opportunity to discover the excitement of designing with people with whom you sit at the table for the first time and sometimes it happens that the energies move in the right direction. It seems to see all the prerequisites for the Edoardo Macchione and Edoardo Gherardini’s project, two students of LABA of Florence, which they won the product contest.

To find more info: www.progettocreactivity.com/creactivity14

– What do you study in LABA?

We study Design.

– Who did suggest you to partecipate at the contest?

It was (responding Macchione, ndr) prof. Angelo Minisci who told me about the event already in the first year and I attended under his guidance, the second and the third year was professor Luigi Trenti that led us to participate.

For me instead (responds Gherardini, ndr) it was the first time and immediately went well. I am currently enrolled in the second year.

– So it’s not the same year you have decided to join together. How did this collaboration took place?

– Let’s say it happened by chance, in a conversation created in lunch break. We have identified our needs about cleaner public transport and we decided to dedicate at this project. The scenario of the conception was a Chinese restaurant, when we found out our mutually hypochondriac dynamics.”

– How have you developed your project?

“The initial idea was a sanitizer ring that would protect our hands from direct contact with the metal, but the evolution of sketches led us to a final form totally distinct from the beginning. This was because we switched from the desire to design a separate object to something integrated with an existing shape on public transport. This allows reduced cost and easier part replacement. In this way we also propose our object as an integrative without changing the line of production companies.

The project around the form developed in steps, we thought first about a spray system to be activated by pressing dedicated buttons, then a shape that worked on ball bearings, finally we married the idea of issuing direct liquid sponge. ”

– Wich materials did you use in your project?

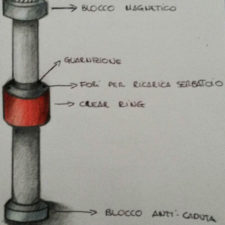

“The material is hygienic and antibacterial to 99.9% and is called SILVER SHIELD. The locking mechanism works with a magnet that secures the support ring. Internally there is a tank that releases the liquid on the sponge every physical contact with a hand. The material in question is already widely used in medical contexts. The towel is made with an antibacterial polyurethane compound treated at the anode. The tank has an access hole for the cleaning fluid charging.”

– Are you thinking about patenting the idea?

“Yes, in fact we have already done it. We protected in two ways: by printing the draft and sending it via mail in a sealed envelope and opening a practice with notary and lawyer. We hope to have an interview with ADI to insert the project into their records and have additional protection.

– Then do you will move to submit your idea at companies?

Surely. What we have in mind is to find a transport company willing to invest in our project. We already know that we will be supported by LABA through synergies, research and collaborations.